In this month’s article we will be discussing some of the most common electrical and physical properties specified by customers when purchasing PZT ceramics for a specific application, how to test for these often specified properties, and some general equipment choices.

Generally speaking, when ordering a PZT ceramic for a specific application it is necessary to specify one or multiple electrical or physical requirements for the component to function as expected in the system. The most common specifications are: Resonant Frequency, Anti-resonant Frequency, Capacitance (dielectric constant K), d33, and some form of coupling. (note: not all of these requirements need to be specified. Most of the measurements listed above can be direct measurements of the component itself, but some, due to changing geometric requirements, are much easier to determine from the easily measurable properties using mathematical relationships.

The easiest way to measure or calculate most properties of PZT components is by using an impedance analyzer. APC uses multiple HP4194 and 4294 analyzers for this reason. The downside for the end user is the cost of such an analyzer. Similar results can be obtained by assembling some basic systems described below.

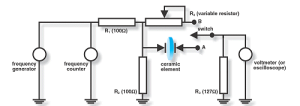

Most easily tested and represented visually by using an impedance analyzer, frequency is important. Resonant frequency is the frequency at which the component exhibits the lowest electrical impedance. Anti-resonant frequency is just the opposite, the frequency at which the component exhibits the highest electrical impedance. It is controlled by a combination of the powder composition and the physical geometry of the component. It is important to note that when the frequency is specified, the physical dimension associated with that frequency not also be specified. It is also necessary to know the desired frequency prior to the manufacture of the components since they will need to be machined to a specific size or shape to have the desired frequency characteristics. If an impedance analyzer is not available, an easy test rig to assemble is shown in figure 1 that utilizes a frequency generator, a frequency counter, a decade resistance box (if also determining resonant impedance), some resistors, a switch and a millivolt meter (or oscilloscope).

Figure 1: Basic circuit diagram for determining resonant and anti-resonant frequency and impedance of PZT components using relatively inexpensive easily acquirable components

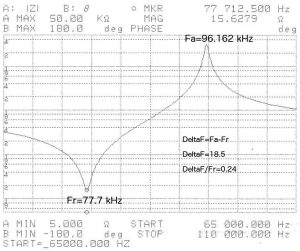

With the switch in the diagram in the “A” position and the component inserted in the system, adjust the frequency generator until the maximum voltage is obtained. This point is the frequency of maximum admittance, or minimum impedance, and is referred to as the resonant frequency. The opposite again is true. Adjust the frequency generator until the minimum voltage is obtained. This is the point of minimum admittance, or maximum impedance, and is referred to as the anti-resonant frequency. The anti-resonant frequency is higher than the resonant frequency, and the difference between the two is referred to as the delta F, or delta frequency measurement. The impedance can also be measured at each of these points using the setup in the wiring diagram above by finding the resonant or anti resonant frequency and noting the voltage reading. Move the switch to the “B” position and set the variable resistor to a value that results in the same voltage reading. The resistance value required to match the noted millivolt output is equivalent to the components electrical resistance. Figure 2 shows a typical frequency plot with the resonant and anti-resonant frequencies, as well as the delta F for a standard 1″ disk sample

Figure 2: A typical frequency plot with the resonant and anti-resonant frequencies, as well as deltaF, for a standard 1″ disk sample.

Capacitance is easily measured using a standard LCR meter. It can also be determined using the impedance analyzer when testing large numbers of components..To standardize the measurement, it is generally performed at drive condition of 1 volt RMS @ 1kHz @ room temperature. Capacitance is a measurement of the components ability to store a charge, and is an important value to know when designing a circuit to drive a component, or designing a component for a pre-existing circuit. The capacitance, combined with the physical size of the component, is used to calculate the dielectric constant (K), a material property.

d33 is a measurement best made directly using a d-meter, although it can be calculated (using specially produced sample parts exhibiting a precise geometry) using the dielectric constant, coupling coefficients, and elastic constants. It is a reference measurement used to determine the efficiency of the material at converting mechanical energy to electrical energy and vice-versa. The efficiency of the component is also related to the delta F described earlier. In general, the higher the delta F, the higher the efficiency of the component. D33 can also be indicative of sensitivity when building sensors using PZT components, although this is not a steadfast rule. It can also be used to determine part polarity, and polarization. If the part geometry is not standard, or there are a number of pieces to test, do yourself a favor and invest in a d-meter. https://www.americanpiezo.com/standard-products/wide-range-d33-tester.html

APC tests 100% of the parts produced for the properties specified by the customer. Serialization and full record of each test are available, for a fee, if requested. 100% testing guarantees each and every component meets customer specifications.

Just as important as testing, packing and shipping ensures the components make it to their destination unharmed and in good physical condition. One of the key factors in adequately packaging the components for shipping is eliminating the opportunity for component-component impact to occur. This can be accomplished by very tightly packing the ceramics in contact with each other, or alternatively spacing the ceramics apart using custom foam liners and plastic trays. APC can also package components in customer supplied packaging for a drop in solution to process automation.

For additional information or for technical assistance please contact your sales associate or visit. www.americanpiezo.com.

This concludes the Ceramic Manufacturing Series of articles. Join us next month for a brief feature on Echo Sounding using PZT, followed by the beginning of the next series of newsletters: The “After Manufacturing” Series starting in June which will highlight different applications for the ceramic components starting with “General Anatomy of Transducers“.

Read More On Piezo Applications

What is the Purpose of a Piezo Motor

Piezo Aiding Advancements in The Healthcare Industry