This month we will be covering electrodes and electrode firing for PZT ceramics. We will primarily be discussing fired-on silver electrodes, but will touch on several other techniques commonly used in the industry.

When determining which electrode system is right for your application it is important to consider the end use of the ceramic component. Will the component be bonded to a substrate or into a system? What type of bonding mechanism will be used? Will soldering be performed on the electrode? Will the component be exposed to an excessively reducing, oxidizing, or other aggressive atmosphere? Will custom patterns be required in the electrode layer? Is the component shear mode? And, if so, will applying and firing a traditional electrode de-pole the material? These are criteria that must be considered when trying to select a suitable electrode system.

Silk-screen applied, fired-on silver electrodes are the most commonly used electrodes in the piezo industry. Other techniques include: Electro-less Nickel (EN) plating, electroplating, sputtering, evaporation, and silk screening of 1 or 2 part metal containing epoxy or polymer low temperature materials. Each has potential benefits and drawbacks and we will briefly discuss each below-

With its relatively low cost, flexibility of application, and ease of firing its easy to see how silk screening silver electrodes has become standard in the piezo industry. For general applications, pastes are formulated with approximately 70-75% silver, 20% organic vehicles and volatile solvents, and 5% glass (for bonding to the ceramic surface). Custom pastes containing silver, platinum, palladium, or sometimes colorants (used to indicate polarity in later stages) can also be manufactured for custom applications. The vehicle system and particle size of the solids in the paste determine its rheology, which is a critical control when silk screening electrodes onto ceramic substrates. Generally a shear thinning paste is preferred for print consistency and ease of deposition.

Application is performed manually or automatically using a custom stainless steel screen with a mesh count ranging from 200 to 325 (openings/inch) depending on the print thickness and resolution required. An approximate wet print thickness can be calculated using the properties of the screen (open area %, mesh thickness, wire diameter). Almost any custom pattern can be applied with this method thanks to the flexibility of screen manufacturing.

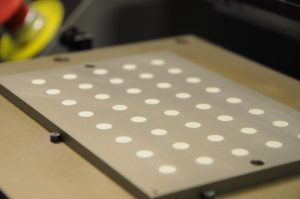

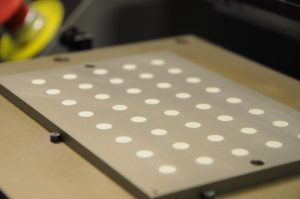

Once the screen pattern and properties are determined and the screen is manufactured, printing can take place. Electrode paste is loaded onto the screen and the screen is evenly flooded with paste. The ceramic components are indexed into pre-manufactured fixture plates. Using light pressure, a squeegee (at approximately 45 degrees to the screen surface) is used to apply shear force to the paste in the screen. The paste reduces in viscosity under the influence of the shear force and transfers to the ceramic components. As the paste recovers to its original viscosity it self levels leaving an even, blemish free surface.

After application, a 15 minute air dry followed by a 15 minute oven dry at 125C is performed. This ensures the layer is stable enough to be handled and that the solvents are fully evacuated from the layer. The process is repeated for the opposite side.

To complete the electroding process, the layers are permanently fired on. It is through this firing process that the remaining organic components are evacuated and combusted from the electrode layer, the glass is softened and penetration into the ceramic substrate occurs (~500-850C) providing a chemical and mechanical bond to the surface. The glass interface layer typically penetrates into the ceramic 1-2 times the thickness of the fired silver layer, making the fired silver process non-ideal for very thin components.

For very thin components (where glass penetration negatively effects ceramic properties) or shear mode components (where high temperature application of electrodes will de-pole the ceramic) EN plating is a good solution. EN plating is a low temperature chemical deposition process in which very thin (<10um) layers of nickel are deposited on the ceramic surface. Excellent adhesion and solderability can be obtained with EN plating making it a great alternative to fired silver. Large economies of scale are also attainable with EN plating.

If custom layers for harsh environments are required, electroplating is another option. By initially strike coating copper or nickel to the ceramic surface to provide a conducting layer, other materials can be electroplated to the strike layer in various combinations and layer thicknesses.

A vacuum based deposition process, extremely thin and complex layer chemistries can be deposited. In the process of evaporation metal sources are heated to a high temperature and ions are driven from the source, through a vacuum, and deposited on the ceramic surface. Sputtering, although also a vacuum process, uses a plasma to drive ions from the source material and transport them to the ceramic surface. Sputtering and evaporation are also low temperature deposition methods that can be beneficial when manufacturing shear mode components.

Another low temperature solution is the epoxy or polymer materials. These materials have the benefit of screen printability making the application of these products very customizable and low cost. The epoxy materials provide very good adhesion and highly conductive layers. Components can then be bonded using similar epoxies, or leads can be attached using the same epoxy resulting in excellent pull strength.

As you can see, there is an electrode solution for almost every application. With adequate consideration of the application and environment the electrode will be exposed to, the perfect electrode can be applied. Once the electroding process is complete, the Poling process can be performed.

For additional information regarding electrodes, electrode patterns, soldering, and shear components please visit www.americanpiezo.com

Be sure to check out our knowledge center on all of our products and services. Contact one of our representatives for additional information.

Read More On Piezo Applications

What is the Purpose of a Piezo Motor

Piezo Aiding Advancements in The Healthcare Industry