This month, we will be introducing the first newsletter in a multi-month series of newsletters devoted to the processes, operations, and equipment required to manufacture piezoelectric ceramics. This month will begin with the in-house manufacturing of our PZT Powders. The coming months will be dedicated to exploring the pressing, sintering, machining, electroding, poling, testing and inspection of piezoelectric ceramics. Ceramics are used in various applications including diagnostic and therapeutic medical ultrasound devices; SONAR; automotive applications, such as knock sensors, buzzers, and back-up sensors; energy-harvesting applications; aerospace applications, such as guidance systems and vibration and noise cancellation; industrial applications, such as flow meters; piezoelectric motors and actuators; and consumer applications, such as humidifiers and BBQ grill igniters. Continue reading for this month’s feature article, the first in the series, “PZT Powder Manufacturing”

The process of manufacturing high quality PZT devices begins by manufacturing high quality PZT powders.

Brian Julius, V.P. Manufacturing / Materials Engineer

Ron Staut, V.P. Technology

The process of manufacturing high quality PZT powders begins by developing reliable formulations, sourcing extremely high purity raw materials, and developing processes and process controls, each contributing to consistent, reproducible, and expected results.

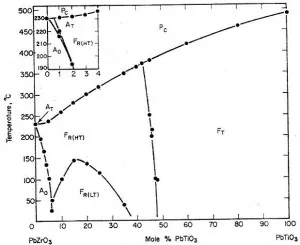

High quality, reliable formulations typically begin as base compositions straddling the morphotropic phase boundary (MPB) in the PbZrO3-PbTiO3 system, as seen in Figure 1. The morphotropic phase boundary is located between the rhombohedral and tetragonal stability fields at the approximate 50:50 mole percent PbZrO3-PbTiO3 composition. Base compositions straddling this boundary yield a large number of potential domain states with both tetragonal and rhombohedral phases possible. *Figure 1 (PbZrO3 – PbTiO3 Phase Diagram (1)).

Next, the desired end use for the material is considered. This will steer the development in the direction of a soft or a hard PZT. Hard PZTs (APC-840, APC-841, APC-880) are physically harder and have lower electrical loss factors and as a result are used in high power applications. Soft PZTs (APC-850, APC-854, APC-855) are physically softer, have higher sensitivity and are most often used in sensing applications.

The determination of a hard vs. soft requirement for the composition is critical in dictating the potential dopants that can be used to modify the base material properties. Examples of some of the dopant materials used in the manufacture of PZT powders are Barium (Ba), Lanthanum (La), Niobium (Nb), Strontium (Sr), Antimony (Sb), and Iron (Fe) oxides. Dopant substitutions are made based on lattice site fit, valence state, experimentation, and experience.

The general flow diagram for powder manufacturing is shown in Figure 2 (Flow diagram – six primary powder operation).

It is critical that only the highest purity raw materials are used.They are evaluated, selected and sourced throughout the world. Selection criteria, in addition to purity, include material activity (surface area), particle size, and limitations on specific deleterious, yet sometimes unavoidable, impurities.

Once the raw materials are selected and approved for use, they are precisely weighed (according to the formulation being manufactured) and transferred to the grinding mills. The ingredients are wet-milled together in their proper proportions using high purity ceramic media, with particle size distribution and slurry rheology being the most critical controls. Precise control over particle size distribution is absolutely essential for the reaction of constituents to form the desired hard or soft PZT phase during the calcining operation.

The mill is then discharged and the product is dried and prepared for calcining. High-purity ceramic crucibles are necessary to guarantee that no chemical contaminants are present in the final product. The calcining operation is carried out, in air, at about 1000°C, where the desired final PZT phase is formed (Figure 3 – APC 850 staged for the Calcining operation).

After calcining, the PZT powder is returned to the grinding mill where homogeneity is ensured, agglomerates formed during calcining are broken down, liquid binder solutions (necessary for pressing) are added, and the material is ground back into a uniform slurry in preparation for spray drying, where water is evaporated from the slurry and dried, spherical, hollow agglomerates of the individual particles are formed. A successful spray drying operation requires experienced operators to regulate the temperature, airflow, and slurry flow within the unit in accordance with the properties of the slurry material, as well as the volume of slurry entering the dryer.

In the spray drying process slurry is pumped, at high pressure, through a small nozzle where atomization into smaller particles occurs (see Figure 4 – water begin atomized into drying chamber representing typical spray pattern). The atomized slurry material is carried by the hot drying air through the dryer (where the moisture is evaporated) and is discharged as a dry powder from the bottom of the chamber.

The purpose of spray drying our PZT material is to produce a free-flowing, binder-containing powder consisting of hollow spheres of narrow agglomerate size distribution, in order to yield consistent die fill and an ideal dry press-able material (see Figure 5 – APC 850 powder, notice the consistent spherical shape and size).

The morphology, particle size, binder content, and moisture content of the dried material are all critical and are controlled by a combination of the slurry properties and the dryer properties and is crucial for the next step: Pressing PZT Powders

Please visit: www.americanpiezo.com/apc-materials/physical-piezoelectric-properties.html to view the characteristics of APC Piezoelectric Materials

Stay tuned next month for “Pressing PZT powders into dense monolithic shapes” as the next installment in the Ceramic Manufacturing Series.

For more information on all products and services, please visit our knowledge center or contact one of our representatives today.

References:

1. Jaffe, B., Cook, W. And Jaffe, H. 1971; Piezoelectric Ceramics

Academic Press Limited, pp. 136

2. Staut, R., Julius, B. 2010, PZT Powder Manufacturing

Ceramic Industry Volume 160, May 2010 Issue 5, pp. 18,19