When subjected to a mechanical force certain crystalline minerals become electrically polarized. Tension and compression generate voltages of opposite polarity, in proportion to the applied force. The converse of this relationship also is true: a voltage-generating crystal exposed to an electric field lengthens or shortens according to the polarity of the field, and in proportion to the strength of the field. These behaviors are the piezoelectric effect and the inverse piezoelectric effect, respectively. Piezoelectric materials have been adapted to an impressive diversity of sensing and action applications, including generation of sonic and ultrasonic signals. For many of these applications there are no practical alternatives.

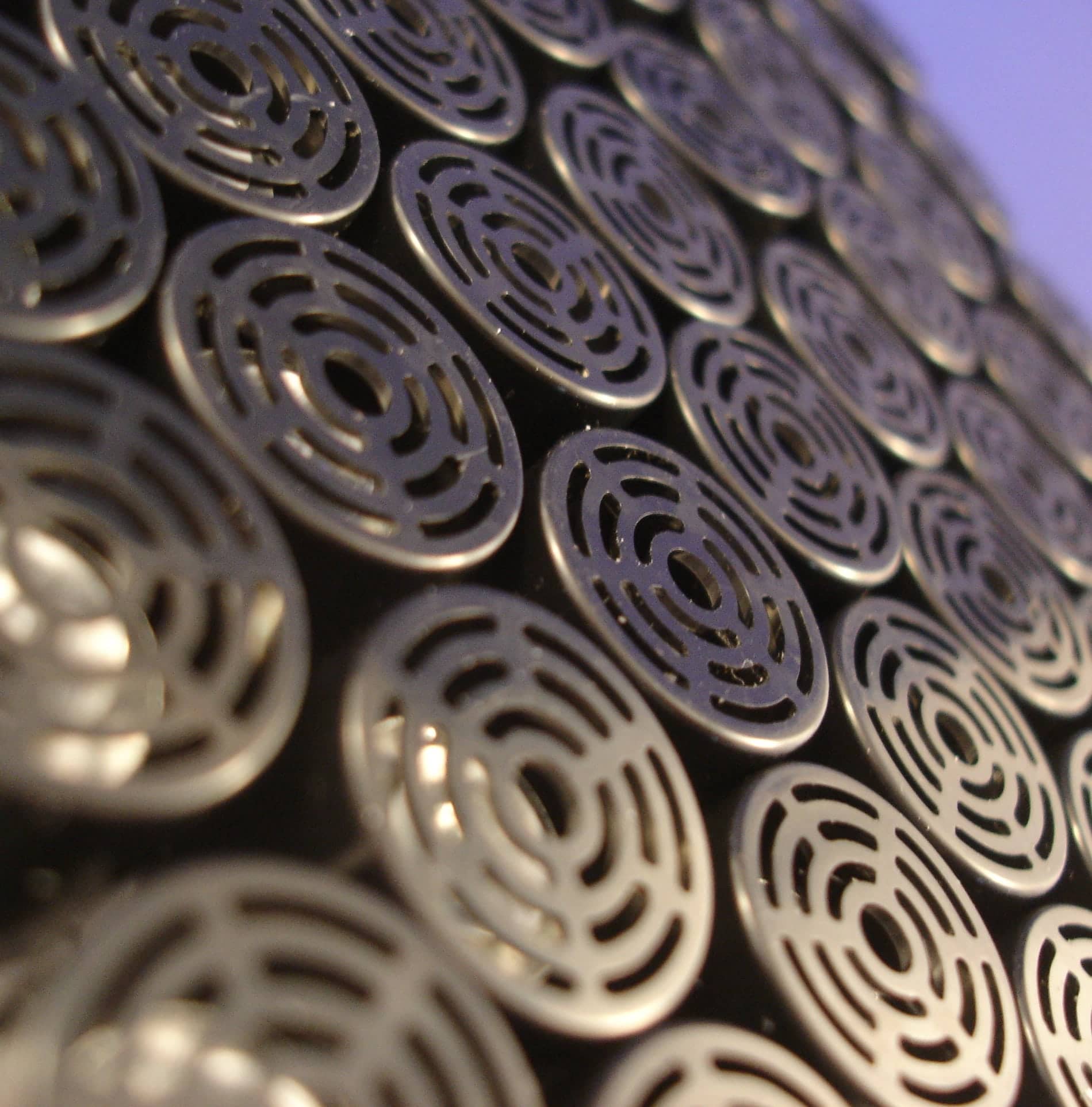

Metal oxide-based piezoelectric ceramics and other man-made materials have enabled designers to employ the piezoelectric effect and the inverse piezoelectric effect in applications for which natural materials are unsuitable. The composition, shape, and dimensions of a piezoelectric ceramic element can be tailored to meet demanding requirements. Further, these materials are physically strong and chemically inert, and they are relatively inexpensive to manufacture.

PC International manufactures its custom piezoelectric elements from a selection of proprietary piezoelectric materials. Our lead zirconate titanate (PZT) materials are manufactured from some of the highest purity raw materials available on the market and have been developed and refined through years of extensive research and development.

APC has produced custom piezoelectric ceramics and PZT materials for over twenty-five years and we would like to be the one to manufacture the piezoelectric ceramics that meet your needs. However, if you would like to produce the piezoelectric ceramics on your own, APC offers many of its unprocessed PZT materials for direct sale to customers.

Speak With An Expert

A ceramic element of suitable composition is made piezoelectric by exposing the element to a strong direct current electric field. When the electric field is removed the element is permanently polarized (poled) and elongated in the direction of the field. Subsequently, compression along the direction of polarization, or tension perpendicular to the direction of polarization, generates voltage of the same polarity as the polarizing voltage. Tension along the direction of polarization, or compression perpendicular to the direction of polarization, generates voltage with polarity opposite that of the polarizing voltage. This conversion of mechanical energy into electrical energy—generator action—is used in fuel-igniting devices, solid state batteries, and other products.