Jump To: PZT Material Properties | Manufacturing | Properties | What is PZT Made of | Popularity of Ceramic | Ceramic Applications

PZT, or lead zirconate titanate (Pb[Zr(x)Ti(1-x)]O3), is one of the world’s most widely used piezoelectric ceramic materials. When fired, PZT has a perovskite crystal structure, each unit of which consists of a small tetravalent metal ion in a lattice of large divalent metal ions. In the case of PZT, the small tetravalent metal ion is usually titanium or zirconium. The large divalent metal ion is usually lead. Under conditions that confer a tetragonal or rhombohedral symmetry on the PZT crystals, each crystal has a dipole moment.

PZT materials, and piezoelectric materials more generally, exhibit a unique range of properties. In a basic sense, if a piezoelectric material is deformed, an electric charge is generated in what is known as the piezoelectric effect. The opposite of this phenomenon also holds true: If an electric field is applied to a piezoelectric material, deformation occurs in what is known as the inverse piezoelectric effect.

PZT is a metallic oxide based piezoelectric material developed by scientists at the Tokyo Institute of Technology around 1952. In comparison to the previously discovered metallic oxide based piezoelectric material Barium Titanate (BaTiO3), PZT materials exhibit greater sensitivity and have a higher operating temperature.

PZT materials supplied by APC International are manufactured from high purity precursors, with properties optimized for specific applications by adjusting the zirconia:titania ration, and/or by including secondary materials. Learn more about the history of piezoelectricity in this resource.

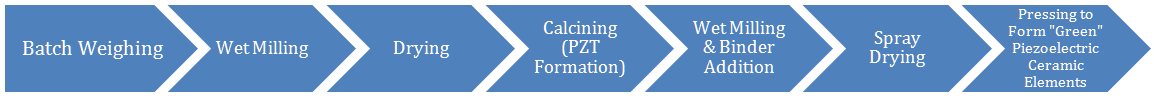

Figure 1:

The process of manufacturing PZT powders consists of six distinct unit operations (See Figure 1). High-purity raw materials are evaluated, selected and sourced throughout the world. Selection criteria, in addition to purity, include material activity and limits on specific deleterious impurities.

Once each material is selected and approved for use, it is precisely weighed, according to the formulation being manufactured, and transferred to wet mills. These ingredients are wet-milled together in their proper proportions to achieve a uniform particle size distribution. Precise control over particle size distribution is necessary to ensure appropriate material activity during the calcination.

Following the wet milling process, the product is dried and prepared for calcining. The product must be calcined in high-purity crucibles to guarantee no chemical contaminants are present in the final product. The calcining operation is carried out in air at about 1000°C, where the desired PZT phase is formed.

It is important to remember that the major ingredient in PZT material is lead oxide, which is a hazardous material with a relatively high vapor pressure at calcining temperatures. Therefore, it is possible to alter the desired composition by allowing too much lead to evaporate during the firing operations. Proprietary measures are employed to ensure lead loss is not a factor.

After calcining, the PZT powder is returned to the mill to ensure homogeneity and to prepare the material for the addition of an organic binding agent. The binder-containing slurry is then fed to a spray dryer, where water is evaporated. A successful spray drying operation requires experienced operators who can regulate the temperatures within the unit in accordance with the solids content of the slurry material, as well as the volume of slurry entering the dryer.

The purpose of spray drying the PZT powder material is to provide a free-flowing product in the form of binder-containing hollow spheres with a narrow particle size distribution. The morphology of the PZT material is crucial to consistently fill die cavities in the dry pressing process when manufacturing piezoelectric ceramics. The uniform PZT spheres of appropriate particle size distribution allow for air escapement throughout the compaction process, yielding lamination-free green ceramic shapes.

PZT was developed around 1952 at the Tokyo Institute of Technology. PZT is composed of the two chemical elements lead and zirconium combined with the chemical compound titanate. PZT is formed under extremely high temperatures. The particulates are filtered out using a mechanical filter. PZT causes a compound to change shape from an electric field.

PZT, lead zirconate titanate, is the most commonly used piezo ceramic today. In general, piezo ceramics are the preferred choice because they are physically strong, chemically inert and relatively inexpensive to manufacture. Plus, they can be easily tailored to meet the requirements of a specific purpose. PZT ceramic is revered because it has an even greater sensitivity and higher operating temperature than other piezo ceramics.

PZT ceramic is used in a wide variety of applications. Soft (sensor) PZT ceramic powders are typically used when high coupling and/or high charge sensitivity are important, such as in flow or level sensors; ultrasonic nondestructive testing/evaluation (NDT/NDE) applications; or for accurate inspections of automotive, structural or aerospace products. Material characteristics include a high dielectric constant; high coupling; high charge sensitivity; high density with a fine grain structure; a high Curie point; and a clean, noise-free frequency response.

Hard (high power) PZT ceramic powders are used when high power characteristics are required, including applications such as the generation of ultrasonic or high-voltage energy in ultrasonic cleaners, sonar devices, etc. Important powder characteristics include a high piezoelectric charge constant (d33); a higher mechanical quality factor that reduces mechanical loss and enables a lower operating temperature; a low dissipation factor that ensures cooler, more economical operation; high dielectric stability; and low mechanical loss under demanding conditions.

Making Electrical Connections to PZT Components

Contact APC International, Ltd. today by filling out a form or call (570)726-6961 to speak to one of our representatives.